An Introduction To Strapping

In this week's blog, we're looking at what strapping is, the different types, and how each coil compares.

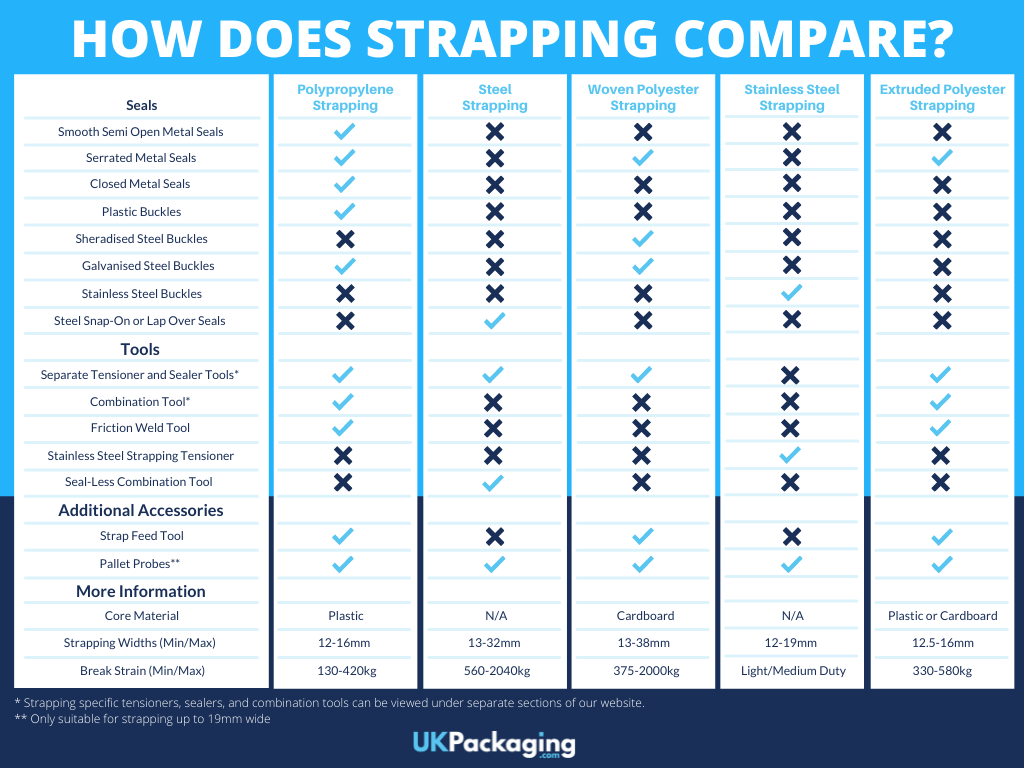

Check out our handy guide…

What is Strapping?

Strapping is widely used across a variety of different industries, primarily for unitizing products from shipping and storage. During typical use, strapping is typically added to products or full pallets either horizontally or vertically. These will also usually be paired with edge protectors in order to help even out the tension in the strap whilst also protecting the goods from any damage caused by the strapping itself. Using strapping to bundle items together typically makes them easier to handle, and can also be useful for securing products to avoid damage in transit.

Which Strapping Should I Use?

Polypropylene Strapping

Polypropylene strapping is one of the most versatile strapping options for many industries, as it can be used with most types of seals and sealing equipment. It is also one of the most common types of strapping, accounting for the greatest proportion of all strapping that is used globally. This is likely because polypropylene is an extremely economical choice for strapping due to the relatively low cost of the raw material. Polypropylene strapping is best used for light to medium duty applications and is ideal for palletising and bundling items that are being transported for short periods of time. As a relatively pliable material, polypropylene has a high elongation and can therefore allow for some movement to absorb any shocks in transit. However, this can mean that the strapping loses some of its tension once it has been applied, making it less suitable for heavier duty goods that need to be held securely and consistently.

Woven Polyester Strapping

Woven Polyester Strapping is a medium to heavy duty strapping that is made from cross woven strands of polyester yarn. This offers a higher resistance to chafing and shearing, making it suitable for heavier and rougher edged consignments. As Woven Polyester is also softer than Steel, it also has a higher elongation and a good elongation memory to hold loads securely yet allow for some shock absorption during transit. This is often seen as being a stronger, safer, and more environmentally friendly alternative to Steel, and is also available as Bale Press Strapping for use in bale presses, or as Composite Strapping, which is coated with a cold glue for increased rigidity and strength.

Extruded Polyester Strapping

Extruded Polyester Strapping is similar in appearance to polypropylene, but it has a higher break strain and is more elastic, so can therefore be used for heavier duty applications. Extruded Polyester offers greater retained tension and recovery properties than standard polypropylene, and can feature either a cardboard or a plastic core.

Steel Strapping

Steel Strapping is the strongest strapping that is available, making it ideal for securing heavy duty, rigid loads. Unlike more flexible strapping materials, steel strapping doesn’t flex, allowing for the bundling of heavy building materials that require a high tensile strapping and very little stretch. Steel can also withstand higher temperatures , and is typically favoured by construction and manufacturing industries that use materials that won’t compress during transit yet require a strong hold.

Stainless Steel Strapping

Stainless Steel Strapping is primarily utilised for its enhanced weather resistance and high resistance to corrosion as opposed to for its strength. Many companies will use stainless steel strapping to secure items outdoors, and it is primarily used in food processing, marine, and medical industries.